UP TO THE MINUTE

Why roof tile adhesives can deliver significant advantages for your business

By Adrian Robledo, director of sales, ICP Group.

Tile roof applications can be profitable jobs for roofers. Find out how roof tile adhesives can help deliver greater efficiency and long-term reliability versus traditional fastening methods.

Clay and concrete tile roofs are an attractive and long-lasting option that continue to be in high demand, particularly throughout the American Sun Belt. There are good reasons why: Depending on the region where they are installed, they can offer a lifetime of 50-75 years while adding dramatic curb appeal to a home.

For roofing professionals, there is an opportunity to seize here. Tile roofing jobs can be highly profitable when they’re performed efficiently and effectively. The use of screws, nails, mortar or wire ties has long been common in tile roof applications. These installation practices come with their many challenges and do not have any warranties.

Luckily, alternative fastening options are gaining traction: polyurethane-based roof tile adhesives. These products offer outstanding adhesion of the tiles to the approved roof decks, delivering higher wind uplift values and additional tile support, all while offering streamlined application and installation with the proper training. With this in mind, let’s take a look at what roofing professionals need to know about roof tile adhesives and how to leverage them effectively.

A closer look at mechanical fasteners

To better understand the advantages that adhesive products can bring to tile roof applications, it’s important to understand the limitations of traditional methods.

First, using screws or nails to secure tiles fundamentally involves penetrating the roof deck with thousands of holes. This practice essentially creates greater opportunity for failure in the future than if the roof deck had not been penetrated. Water ingress and structural performance issues are among the greatest threats here.

Then there is the matter of proper installation. Too loose of an insertion with a nail or screw can contribute to future performance issues, particularly in high-wind environments. Too forceful of an insertion, meanwhile, can cause a roof tile to crack or break. There are some areas that also require flashing cements to be applied over all penetrations, which can add additional labor and drive up costs.

Instead, installing clay and concrete roof tiles with a high-performance polyurethane adhesive can effectively eliminate these concerns. Adhesives create a strong bond between the roof deck and tile without requiring the installer to puncture the roof deck (depending on the roof pitch and local building code requirements). This process also contributes to greater uniformity across the roof as a whole, eliminating the variance between too-tight or too-lose nail or screw insertions.

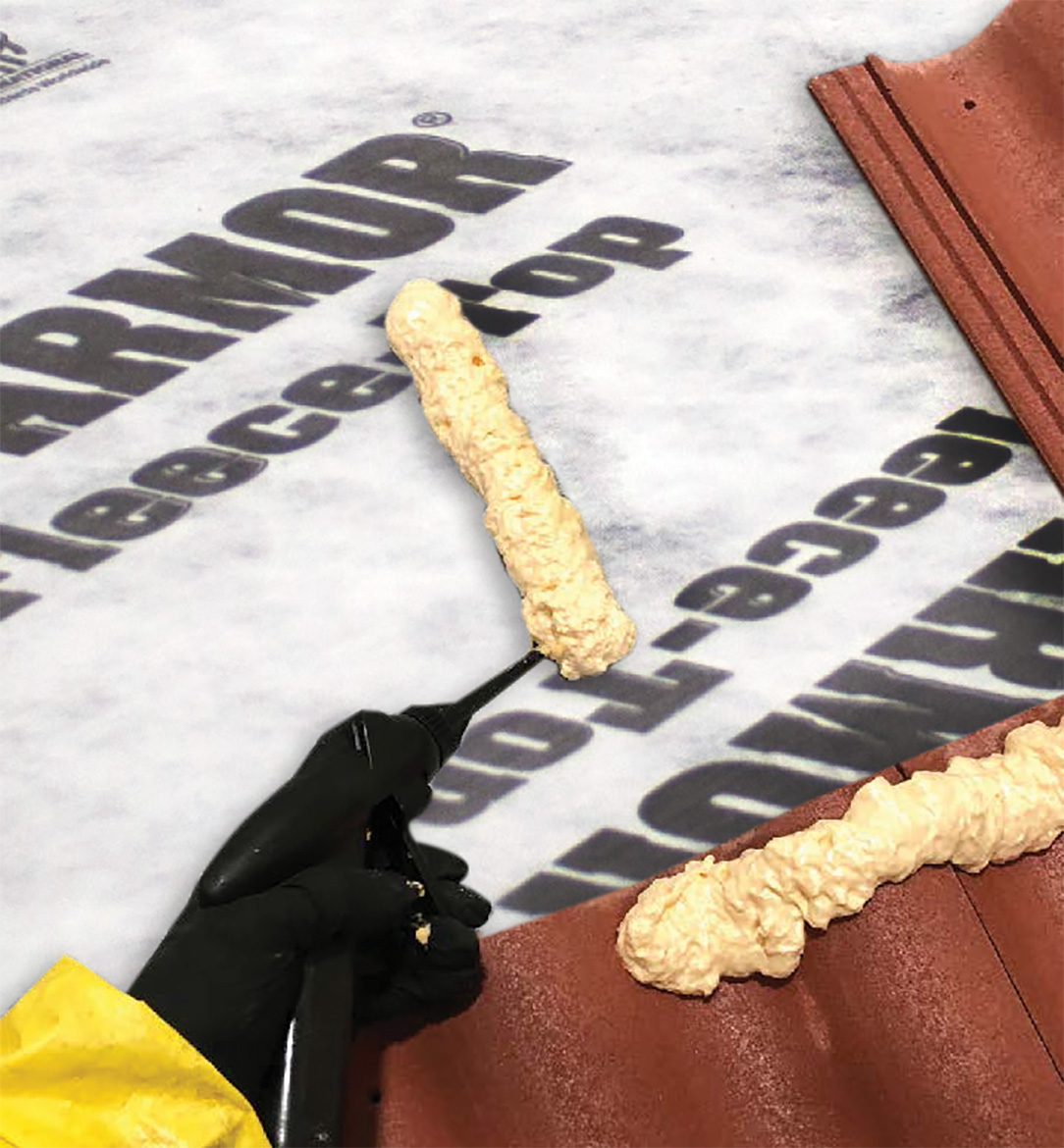

Adhesives can also significantly cut down labor costs associated with clay and concrete roof tile projects. Because adhesives are typically dispensed through convenient and reliable gun/hose assemblies, the installer can spray adhesive and secure tiles more quickly and efficiently. A well-trained crew can typically complete a standard roof tile job in half the time it takes with mechanical fasteners.

One-component adhesives versus two-component adhesives

Polyurethane roof tile adhesives can be divided into two primary categories: one-component and two-component.

- In one component adhesive products, all chemical and raw material components are combined and the adhesive moisture-cures upon dispensation.

- Two-component adhesives’ adhesion chemistry and other materials are kept separate (A-side/B-side); the chemical reaction begins once the two components are mixed together in the application assembly nozzle. These components are fed through hoses up toward the roof workspace and are combined at the point of application.

While both one- and two-component adhesive options will provide high levels of performance, there are some key differences that may make one more suitable for a given application than the other.

Two-component polyurethane adhesives, for example, maintain the highest available levels of wind uplift performance. Third party lab testing protocols and adhesive manufacturers code approvals show higher allowable overturning moment testing data for two-component systems. Depending on the paddy size, tile profile, paddy placement and gram weight, a properly installed two component adhesive systems have the ability to withstand a category 5 hurricane. Two-component options can also deliver additional tile support, contributing to higher break strength and overall long-term durability.

One-component options, by comparison, also maintain high levels of performance, but have their own unique advantages in terms of ease of use. Applicators are able to move around the roof area easily since these come in handheld, user-friendly cylinders. Additionally, multiple applicators equipped with individual cylinders can help complete a job more quickly. Single-component systems’ portability also lends itself to easier application around hips, ridges, cut pieces and trim tiles. These products have high yields, enabling roofers to maximize the number of tiles that can be secured with a single tank of product.

Both one-component and two-component polyurethane adhesive systems can bring their own unique advantages to a roofing project. For example, APOC professional roofing products offers both one-component and two-component systems. APOC Polyset® RTA-1 roof tile adhesive is a one-component system that offers speed, efficiency, and high performance, while APOC Polyset® AH-160 roof tile adhesive is a two-component system that delivers superior holding power for the toughest applications. And while the selection of one system over another typically comes down to contractor preferences, adhesive professionals who are armed with the right information on the benefits of each can help guide them to the right choice.

Both one-component and two-component polyurethane adhesive systems can bring their own unique advantages to a roofing project. For example, APOC professional roofing products offers both one-component and two-component systems. APOC Polyset® RTA-1 roof tile adhesive is a one-component system that offers speed, efficiency, and high performance, while APOC Polyset® AH-160 roof tile adhesive is a two-component system that delivers superior holding power for the toughest applications. And while the selection of one system over another typically comes down to contractor preferences, adhesive professionals who are armed with the right information on the benefits of each can help guide them to the right choice.

Why training matters

When evaluating polyurethane adhesives for your concrete and clay tile projects, it’s important that you and your installers have been trained on proper application.

Various building officials, inspectors and municipalities might require roofing contractors to have been trained in proper product use by the manufacturer. Not only will this help ensure that the job is performed effectively but will help ensure your project goes smoothly. To those ends, APOC offers its Certified Applicator Training for its product lines, enabling professionals to deploy its Polyset one- and two-component roof tile adhesive systems with confidence.

Indeed, properly trained teams can deploy clay and concrete roof tile adhesives to deliver efficient, high-quality work for your customers, allowing you to move from job to job more quickly and with enhanced confidence. Overall, roof tile adhesives offer a wide range of benefits for tile roof applications. Products that have been formulated for the highest levels of performance and ease of use can contribute to more reliable and more durable roofs while enabling professionals to work more efficiently.

About ICP Group

With over 20 years of roof tile and adhesive industry experience, Adrian Robledo is Director of Sales for ICP Group and oversees the brand’s APOC® Polyset Steep Slope polyurethane roofing adhesives. He is dedicated to helping roofing professionals understand the value of proper training and tile installation methods for concrete and clay roof tiles. His passion, commitment, technical knowledge and service to his customers have helped him build a solid reputation as one of the industry leaders in the residential roofing category. To learn more about roofing tile adhesives visit www.APOC.com. Adrian can be contacted at arobledo@icpgroup.com.

Learn more about ICP Building Solutions Group in their Coffee Shop Directory or visit www.icpgroup.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In