UP TO THE MINUTE

Roofing materials to consider for each job

By Corey Mann, Leap.

Your roofing project’s success starts with the right materials.

With every roof needing its own unique blend of components, understanding which materials to consider for each job isn't just useful — it's crucial. Whether you're a seasoned contractor or new to the trade, our team here at \ can help you understand the ins and outs of these materials and how they can make all the difference in delivering quality work that stands the test of time.

Roofing materials list to consider for each job

A residential roofing job demands various materials. Each component plays a vital role in the roof’s durability and appearance. For example, the roofing materials list below includes the manty types of products you may or may not need for a residential roofing job. Some are necessary for every job, while others are essentially a choice between you and the homeowner during the sales process.

- Asphalt shingles: The most common roofing material in North America. They come in various colors and styles.

- Metal roofing: Durable and energy efficient. Metal roofs can last up to 50 years.

- Wood shingles and shakes: Provide a natural look. Cedar is a popular choice.

- Slate tiles: Known for their longevity and aesthetic appeal. They can last over 100 years.

- Clay and concrete tiles: Resistant to fire and wind. These tiles are suitable for hot climates.

- Synthetic roofing: Mimics other materials but offers better durability and less maintenance.

- Underlayment: Protects the roof deck from moisture. Options include felt and synthetic underlayment.

- Roof decking: The base layer that supports the roofing materials. Typically made from plywood or OSB.

- Flashing: Metal pieces that prevent water penetration at roof joints.

- Drip edge: Installed at the edges of the roof to direct water away from the fascia.

- Ventilation: Ensures airflow in the attic. Includes ridge vents, soffit vents and exhaust vents.

- Fasteners: Nails, screws and other fasteners to secure roofing materials.

- Sealant and adhesives: Used to bond materials and prevent leaks.

- Roof insulation: Helps in maintaining energy efficiency.

- Gutters and downspouts: Directs water away from the building’s foundation.

- Safety equipment: Harnesses, ropes and other gear to ensure worker safety.

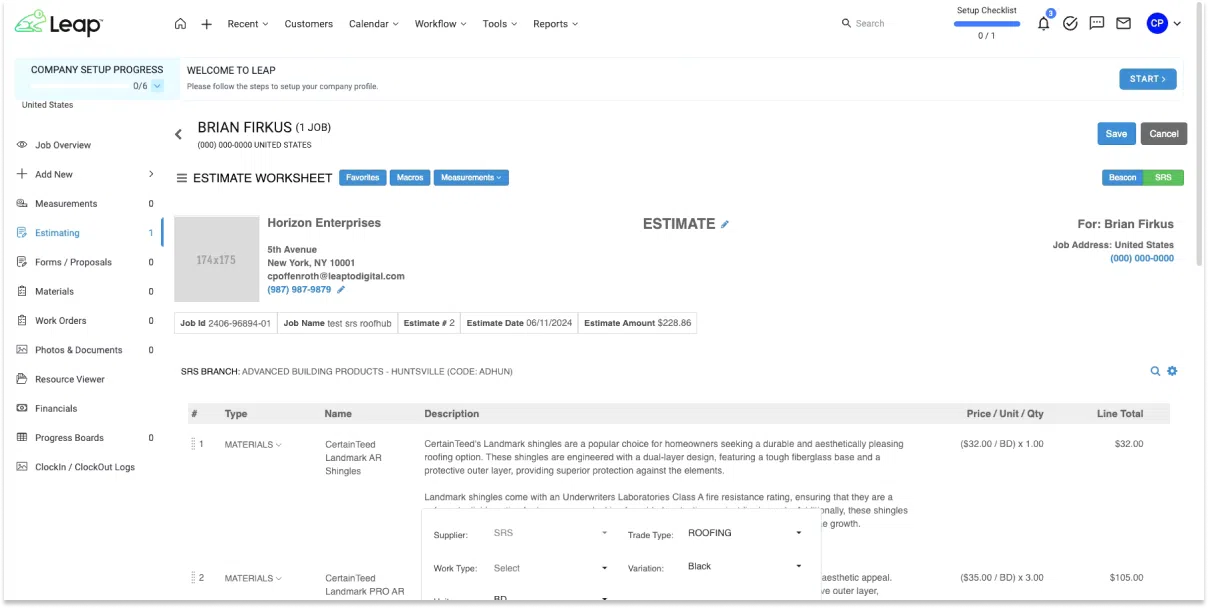

As you can see, there’s a variety of materials that can go into every roofing job. And in general, many contractors struggle with ordering materials that can cause delays due to shipping or inaccurate calculations.

Calculating the right amount of roofing materials

Ordering the correct amount of materials is crucial to avoid waste and extra costs. So, here’s how to do it:

- Measure the roof: Measure the length and width of each roof section. Multiply to get the area.

- Calculate the total area: Add up the area of all sections. Remember to include dormers and other projections.

- Determine the pitch: The roof’s steepness affects the material amount. Use a pitch factor in your calculations.

- Account for waste: Include an additional 10-15% for waste, especially for complex roofs.

- Calculate shingles or tiles: Most shingles come in bundles that cover a specific area. Divide your total area by the coverage per bundle.

- Estimate underlayment: Measure the total roof area. Add extra for overlaps and wastage.

- Measure flashing and edging: Determine the linear feet of valleys, eaves and rakes.

- Count fasteners: Calculate the number of nails or screws based on the number of shingles or tiles.

- Include extras: Don’t forget ventilation, sealants and other accessories.

Ordering materials can be a hassle if you don’t have the right supplier and systems in place. Fortunately, new roofing technology has streamlined this process and made it easier for contractors to place orders faster. Not only can this be done by creating a roofing materials list within the software, but it ensures your materials arrive on time.

Recommended For You

Beacon expands digital platform to support Canadian customers

Read More ...

Filling a gap in the coatings world

Read More ...

Supporting marines from the ground up

Read More ...

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In