UP TO THE MINUTE

The 7 steps of an adhesion test

By Progressive Materials.

Check out this step-by-step guide to see if silicone is right for your roofing project.

Silicone roof coatings are a popular option for protecting and extending the lifespan of a roof. Some of the advantages of this coating treatment include better weather resistance, waterproofing and reflectivity. By better resisting damage from elements such as UV rays and moisture, silicone makes maintaining a roof easier and the overall building more energy efficient, lowering management costs.

But how do you know if silicone will work on each unique roof? An adhesion test is one way to tell if your project is ready for silicone or if you need to take further steps prior to coating application. The experts at Progressive Materials have explained each step and can also provide their customers with a free adhesion test if the customer emails their Regional Manager here.

The basics

An adhesion test measures the adhesive characteristics of a product by measuring the amount of force it takes to separate that product from a test surface. For our industry, this test determines whether silicone will properly adhere to a roof substrate. Progressive Materials’ TJ Flick said the D903 adhesion test is the American Society for Testing and Materials’ standard test for roof coating adhesion. PM uses D903 because it is a part of the wider D6694 umbrella tests for silicone roof coatings. “We are required to pass D903 to say our coatings adhere to the standard D6694 tests,” TJ said.

Why test?

Testing adhesion is crucial because PM’s top-quality silicone cannot offer its waterproofing capabilities and other benefits if it doesn’t stick to the roof. In rare occurrences, moisture under the roof substrate or other underlying issues can cause an adhesion failure. The D903 test can help identify these failures prior to coating. This will save you lots of time, money and hassle if the roof is, for some reason, unable to be coated.

*Please note that when silicone won’t stick to a roof after an initial adhesion test, this doesn’t necessarily mean that coating will never stick. Sometimes a more intentional cleaning, primer or removal of problem areas can prepare an area for coating without much effort or additional cost.

Testing step by step

To see a step-by-step video detailing the right way to do an adhesion test, click here. Otherwise, you can follow these simple seven steps:

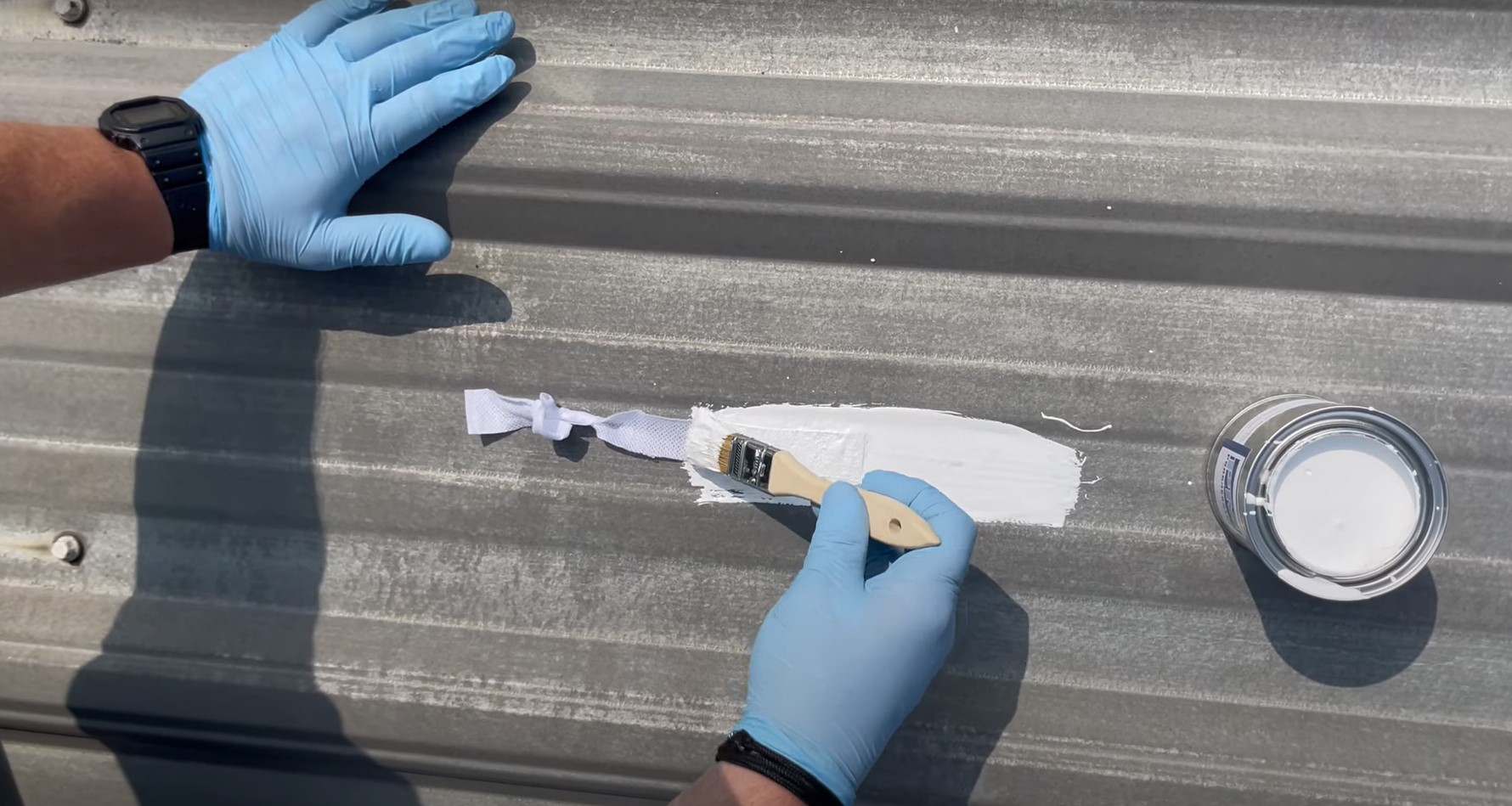

- Thoroughly clean the surface where the test is going down with a wet rag. Make sure the surface is completely dry after cleaning before applying any silicone. Silicone will not adhere to anything if water is present.

- Use a brush to apply a thin layer of silicone to the area.

- Place one end of the pull test strip fabric into the silicone.

- Use brush to apply another top layer of silicone to the fabric.

- Dab a small amount of silicone on the un-coated side of the fabric.

- Let the test cure for at least 24 hours.

- Pull up on the uncoated fabric. You have good adhesion if the fabric is hard to pull off and there is silicone left on the substrate after it’s pulled. If the fabric pulls off with all of the silicone, you have poor adhesion. You need to either try a primer, make sure the surface was clean and dry or look for underlying issues (moisture under the substrate, etc.)

Original article source: Progressive Materials

Learn more about Progressive Materials in their Coffee Shop Directory or visit www.ProgressiveMaterials.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In