UP TO THE MINUTE

Innovating the future

By Emma Peterson.

Learn about how product and equipment design helps mitigate the ongoing labor shortage.

If you’re a part of or know anyone in the professional trades, whether it be contracting or roofing or plumbing, you’ve probably heard the phrase “labor shortage” before. This is because the lack of skilled laborers and workers entering the professional trades has been a growing issue for years now. In this episode of Roofing Road Trips®, Heidi J. Ellsworth and Mike Steele sat down to talk about this issue and how Tremco sees innovation as a part of the solution.

Mike is the VP of product and technical solutions for Tremco and has been working with the company since 2013. He shared a bit of his background, saying, “I'm actually a third-generation roofer, first generation sheet metal worker before coming to Tremco and started out as a technical support specialist and worked my way through the organization to where I am today.” Throughout that time he has seen the issues the shortage of skilled labor is causing and the different ways members of the industry are trying to get more people interested in the trades.

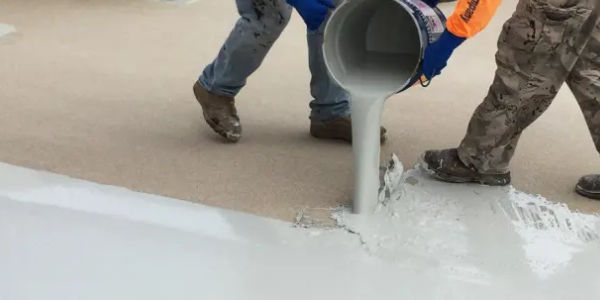

One of the ways Tremco has responded to this issue is in their product development. Mike explained, “There are products on the market today that are really hard to install and take a lot more people on the roof. The idea behind our product development is how do we take a typical tear off crew of six down to four? It's really about not only saving time per person, but also saving the amount of people you need on the roof.” An example of this is Tremco’s AlphaGrade™ roof restoration system. When traditionally working with gravel-surfaced built up-roofs (BUR) you would often have to perform an entire roof replacement which is very expensive, labor-intensive and disruptive. Mike explained that, with AlphaGrade “you're not tearing off a roof, so there isn't that tear off crew needing people on the ground, making sure the dumpster is not overflowing, people cutting the roof, et cetera. You're leaving what's in place intact minus getting rid of any wet insulation or damaged plies, and so forth. And then you begin the restoration project process. So you're not having someone dedicated to mixing because you're using the AlphaGrade dispensing equipment.”

In addition to creating products that require less labor in the field, Tremco aims to increase the accessibility of the field by designing equipment that makes it slightly less labor intensive. Heidi and Mark discussed this, saying, “There’s a shift into ‘roofing doesn't need to be as hard as it was,’ and it was very, very hard work. Roofing is still hard work, but we're starting to make those changes through technology, through innovation that is going to make more people want to be involved, especially when you have equipment, robotics, all that kind of stuff.”

Read the transcript or Listen to the entire conversation to hear more about Tremco’s innovative products and how they are helping the industry.

Learn more about Tremco in their Coffee Shop Directory or visit www.tremcoroofing.com.

About Emma

Emma Peterson is a writer at The Coffee Shops and AskARoofer™. Raised in the dreary and fantastical Pacific Northwest, she graduated in 2024 from Pacific University in Oregon with a degree in creative writing and minors in graphic design and Chinese language. Between overthinking everything a little bit, including this bio, she enjoys watching movies with friends, attending concerts and trying to cook new recipes.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In